Your favourite perfume accompanies you every day, like a second skin. It is your olfactory signature, and follows you everywhere. And yet it still keeps its little secrets, like how it was actually made! At Sillages Paris, as perfume lovers, we decided to lift the veil on the art of perfumery. Here, we tell you everything about how your perfume is made. From the raw materials to the bottle that will end up in your bathroom, let’s discover together the secrets of perfume making.

1st step of perfume making : raw materials

The first step in perfume making is to extract the natural raw materials, or to create synthetic materials. And there are several techniques to obtain them.

The enfleurage

It is the oldest technique used to obtain scented essences. It is a method which, as its name suggests, allows for the extraction of flower essences. The enfleurage can be performed either hot or cold.

Cold enfleurage is a very old process and is seldom used nowadays. It is still sometimes used to treat very delicate flowers such as jasmine, rose or orange blossom, but its use is now quite rare. This technique is somewhat tedious (and not vegan at all!).

The technique involves placing the petals on a plate coated with odourless animal fat. Next, the petals are replaced every 24 or 48 hours so that the fat absorbs as much of the odour as possible. Once saturated with scented molecules, the fat is heated (so that it melts) and mixed with alcohol. The alcohol and fat then separate, just like when you mix water and oil in a glass! After filtering the alcohol containing the odorous materials, you finally get an absolute.

Hot enfleurage follows the same principle, but is used for more resistant flowers. The only difference is that instead of placing the petals on cold solid fat, they are immersed in a bath of hot melted fat. In the same way, the petals are renewed, and an absolute is obtained by using alcohol.

Fun fact: for those who have read it, this is the technique used by Jean-Baptiste Grenouille in Le Parfum, by Patrick Süskind!

The distillation

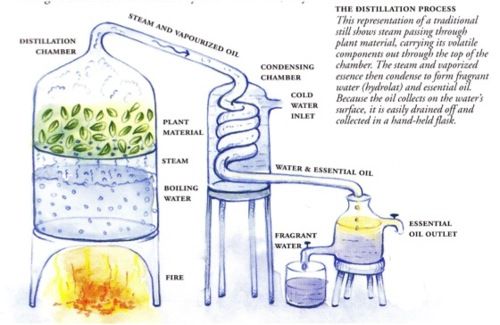

Over the centuries, the techniques for making perfume have evolved, such as the distillation process. This process consists of heating water at high temperature with the plants from which the essence is collected. When heated, water vapour is formed and draws with it the odorous molecules.

The water vapour then cools in the pipe and recondenses (turns back into liquid water) and is separated from the essential oil. Again, like water and oil separating if you try to mix them in a glass!

The expression

The expression is the name given to the technique used to extract citrus essences. Contrary to what one might think, it is not the juice of citrus fruits that are used in the making of perfumes. Rather, it is the essence contained in the small alveoli in the peel, which can be discerned on the surface of the fruit’s skin when you look closely. This is the essence that stings our eyes when we peel a clementine! Do you know what we’re talking about?

Well, the process is exactly the same! When we peel a clementine, we collect droplets from these small cells that are broken during the peeling process. The expression is based on the same technique, which involves drilling small holes in the bark to recover the essence. We thus obtain a liquid which is a mixture of water and essential oil. The essential oil is then separated from the water with a centrifuge.

Solvent extraction

Solvent extraction involves mixing plants with a solvent (methanol, ethanol, benzene, etc.) that is heated. With the heat, the solvent evaporates, and a waxy material loaded with essences is obtained: the concrete.

This concrete is mixed with alcohol (as in cold enfleurage) so that the odorous molecules can pass through it. Finally, the filtration of the alcohol produces an absolute.

Synthetic molecules : the great catalysts of modern perfume making

Since the middle of the 19th century and developments in chemistry, synthetic molecules have been used in many fields. And perfumery is no exception! It is now possible to create all types of odorant molecules in a laboratory: either to reproduce natural odors, or to create scents that come directly from the imagination of perfumers. This process has two major advantages.

They are vegan and responsible!

Firstly, synthetic ingredients have made it possible to replace animal materials, which have long been very popular in perfumery. Ambergris (sperm whale), civet (musk cat), castoreum (beaver), and musk tonkin (chevrotin) were very very popular ingredients from the 16th to the 19th century. Mostly derived from glands located near the genitalia of animals, their carriers had to be killed to recover their essence. Their strong smells (of sex and excrement) were appreciated for their sensuality. But also for their ability to give fullness and longevity to the perfume. Since then, the creation of synthetic materials has made it possible to reproduce their qualities, without their shortcomings (the smell of excrement and the killing).

Moreover, synthetic materials also make it possible to replace plants, trees, and flowers facing extinction! For example, Oud wood is extremely valuable and popular in luxury perfumery. This over-exploited tree is now protected by the CITES convention (Convention on International Trade in Endangered Species of wild fauna and flora), which regulates its commercialization.

They give free rein to the Perfumers’ creativity!

Secondly, synthetic ingredients push the limits of Perfumers’ creativity. Indeed, certain smells can’t be extracted naturally by the processes seen above (like fruits, for example, or nuts). And some notes simply don’t exist in their own state (like marine notes, or the “cupcake” note).

At Sillages Paris, our eau de parfums contain at least 80% natural ingredients. And we use synthetic ingredients in two ways: as a replacement for animal matter, and when the molecules don’t exist directly in their natural state. Also, all our synthetic ingredients are 100% safe and made from molecules found in nature. For example, the green notes (synthetic molecule) are created from violet leaf molecules (extracted naturally).

Two other advantages for large-scale perfumery

Synthetic ingredients have other advantages for major brands looking to reach as many customers as possible with the same perfume.

First of all, they ensure that the perfume will have the same effect on all skin types. While natural ingredients add strength, longevity, and complexity to the fragrance, they react differently to different skin types! Synthetic ingredients are linear and, therefore, stable.

Lastly, synthetic ingredients are often less expensive than natural ingredients. Extracting natural ingredients is often a long and laborious process, and it usually requires a lot of raw materials to produce just a small amount of essential oil. This partly explains why luxury perfumes are so expensive. For this reason, the use of synthetic ingredients can save brands a lot of money! However, it is important to note that there are several levels of quality in synthetic molecules.

2nd step of perfume making : assembling the essences

The work of the Nose in perfume making

The Perfumer, also known as the Nose, has about 5,000 ingredients to make up their composition. Typically, a perfumer assembles about a hundred (and sometimes several hundred) of them to create a perfume like those found on the market.

So it’s a very complex and extremely precise job. The Nose will imagine formulas that are developed in percentages: 10% of essence A, 3% of essence B, 0.2% of essence C, and so on. They reason in kilos and grams and not in millilitres as one might think.

Once their ideas for formulas have been decided, they will test them. This is the impressive genius of the Perfumer: it all happens in their imagination, before testing out their creations in real life! They can mentally reconstitute and assemble smells. And it’s a very complex exercise as each ingredient has to fit perfectly into the composition, and achieve a balance. So, in most perfumes, you won’t smell all the ingredients because some of them are present in tiny quantities. But each one is important as they all contribute to the overall harmony. This explains why many people say they hate patchouli, even though it is present in so many successful perfumes! As for our perfumers, they have carte blanche to come up with the most beautiful formulas, with no creative or budget constraints.

A perfumer will thus conduct several trials before deciding on a final formula. At this stage, he or she obtains what we call a concentrate. It’s a mixture composed solely of pure essential oils, which are then diluted with alcohol to obtain the fragrances we know.

The olfactory pyramid

The Nose carries out this work of creation by following a pattern: that of the olfactory pyramid. It designates the classification into top notes, middle notes, and base notes. This classification depends mainly on the nature of the molecules, depending on whether they are more or less volatile.

The top notes are the most volatile. They are the ones you smell first and that last from a few seconds to a few minutes. The middle notes last between 15 minutes and 4 hours. Finally, the base notes last between 2 and 24 hours.

3rd step of perfume making : the creation of the final juice

Dilution of the concentrate

The Perfumer creates a concentrate composed of a blend of pure raw materials. This concentrate is then diluted, usually in alcohol, to obtain a “juice”. Alcohol is particularly well suited to this use for the simple reason that it evaporates very quickly. Thus, when perfume is applied, only the odorous molecules remain on the skin (or the fabric or hair).

This dilution makes it possible to obtain different concentrations, depending on whether you want to create a fresh eau, an eau de cologne, eau de toilette, eau de parfum, or a perfume. In each case, we get what is called the juice.

Maceration of the juice

After the concentrate has been diluted in alcohol, the resulting mixture will macerate for several weeks to achieve the optimum result. The next step is the icing, which involves cooling the juice to around 0°C so that the last excess waxes solidify. This excess is then filtered off, leaving behind a purified and clear juice.

The last step before bottling is usually colouring. Many perfume houses use dyes to tint their juice to make it more visually appealing. They use a mixture of dyes and UV stabilizers to prevent the colour from fading.

At Sillages Paris, we do not use dyes. Our juices have the colour of the ingredients they are made from. It’s just as pretty, and it’s natural!

That’s it, you know everything! Or almost? If you have any questions or a suggestion for a blog post, email us at [email protected]!

And in the meantime, if this has inspired you to create your own personalized perfume, click here 😉.

Let’s keep in touch ! Follow us on Instagram 🙂

Social